Crafted with Purpose.

Delivered with Precision

Our Portfolio showcases the depth and versatility of our fabrication expertise. From custom-machined components to fully finished assemblies, each project reflects our commitment to precision, quality, and customer satisfaction. At Rostek Applications, we take pride in delivering complex parts and unique builds across a variety of industries—proving our capability to adapt, engineer, and execute to exacting standards. Whether it's a one-off prototype or a full production run, our work speaks for itself.

01

Spur Gears

This precision-engineered spur gear was printed on our Markforged industrial 3D printer using Onyx composite material, selected for its high strength-to-weight ratio and dimensional stability. Reinforced with continuous carbon fiber, the gear exhibits exceptional durability and resistance to wear, making it suitable for demanding mechanical assemblies. The fine layer resolution and fiber reinforcement strategy ensure tight tolerances and operational efficiency.

This gear showcases Rostek Applications' ability to produce functional components with complex tooth profiles and optimized strength using additive manufacturing. Designed for high-performance machinery, this component reflects our capability to rapidly iterate and manufacture low-volume precision parts for production or R&D applications.

02

Custom Aluminum Part for High-Volume Assembly

This custom aluminum assembly was designed in-house by the Rostek Applications engineering team and manufactured using our high-precision Flow waterjet system. The part features intricate internal contours and clean edge finishes, demonstrating our ability to achieve tight tolerances without heat-affected zones. Designed for structural integration in a larger assembly, it highlights our expertise in both CAD-based design and advanced material processing.

This custom-designed part was waterjet cut to exacting specifications, optimized for strength, weight reduction, and repeatability. Engineered by the Rostek Applications design team, the part demonstrates our ability to go from concept to production-ready hardware quickly and efficiently. The complex geometry and multiple hole profiles illustrate the versatility of our Flow waterjet technology for prototyping or short-run manufacturing.

03

Carbon Steel Top Cover Assemblies

These custom carbon steel top cover assemblies were designed and fabricated by Rostek Applications to meet the demands of a high-volume production environment. Precision-cut on our Flow Waterjet system, each component was welded in-house and finished with a high-durability powder coat to ensure long-lasting performance in rugged operating conditions.

This project demonstrates our ability to deliver consistent, repeatable quality across large-scale fabrication runs, with full control from design through final finishing.

04

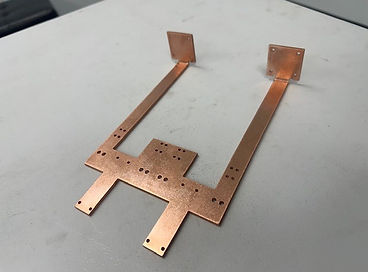

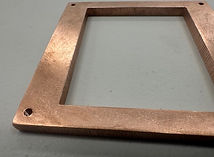

Custom Formed Copper Assemblies

These precision components were manufactured using a combination of waterjet cutting, CNC milling, and CNC press brake forming techniques. Made from high-conductivity copper, these parts showcase our ability to process non-ferrous metals with high accuracy and minimal thermal distortion. The combination of thermal and mechanical processing ensured tight dimensional tolerances and clean, burr-free edges — ideal for electrical or structural applications requiring both conductivity and form stability.